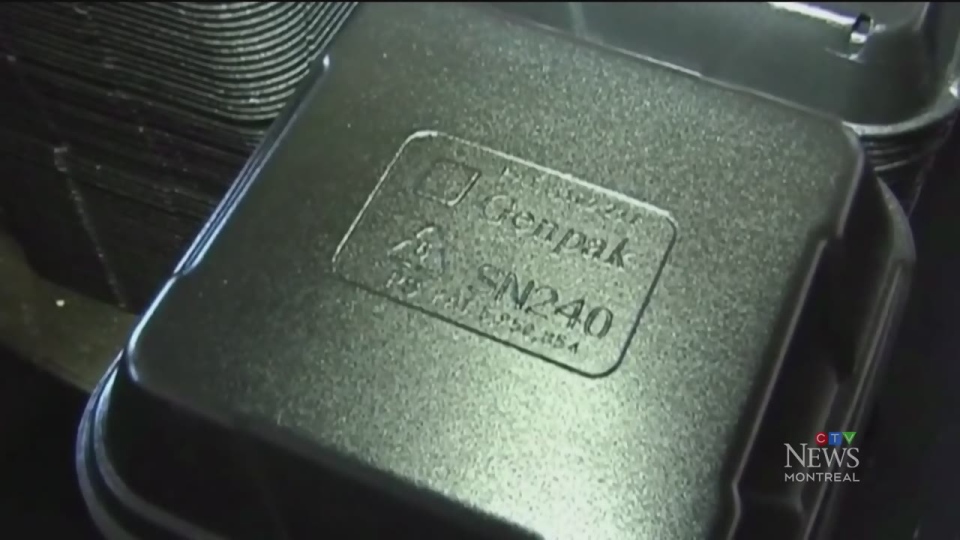

MONTREAL -- A new partnership between engineers at Montreal’s Ecole Polytechnique and Pyrowave, a start-up based in Valleyfield, Quebec, are working on new ways to recycle Styrofoam and other plastics that are generally difficult to recycle.

Styrofoam mostly ends up in landfills around the world, even though it's a frequently-used product affecting our daily lives. Pyrowave developed a technology using microwaves that is expected to change how these kinds of plastics are recycled, a method it says is far better for the planet.

“It's an essential product but its end of life is less than optimal,” said Virginie Bussieres, Pyrowave’s Vice-President of Communications. “Our technology is a platform that with microwaves brings back plastics to their original state and we're starting with polystyrene, plastic number six, also called Styrofoam, which is a hard-to-recycle plastic.”

The join project has received $280,000 in funding from the Natural Sciences and Engineering Research Council of Canada (NSERC) to further their research into the use of microwaves in chemical processes, as pressure on industries to reduce their carbon footprint continues to rise.

“Obviously citizens are asking for it, governments in many countries are adopting new laws to that effect to encourage better recycling,” said Bussieres.

The high degree of instant heat provided by microwaves reduces energy consumption and has a strong potential for reducing greenhouse gases on an industrial scale, according to the research team.

The technology was developed in partnership with Montreal’s Ecole Polytechnique. The process begins by first melting crushed Styrofoam. It turns into a brown and mostly unusable substance. Pyrowave then uses a giant microwave oven, to turn the contaminated melted plastic into gas. Once cooled, the gas returns to a pure liquefied plastic, ready to be used again for just about any plastic product.

According to Bussieres, the result is a virgin-like product that can be used to create new plastic packaging, and can even be converted into synthetic rubber.

“Microwaves are common in our kitchens, our family has one and use it on a daily basis,” said Bruno Blais, a professor at Ecole Polytechnique who helped develop the technology.. “Industrially their use has been quite limited so the process we patented is one of the first industrial use of microwave technology.”

Initial tests are taking place in Ecole Polytechnique labs, but later researchers will test it on an industrial scale, using Pyrowave’s industrial reactor.