The consortium building the new Champlain Bridge said many of the parts arriving from overseas are not as good as they should be.

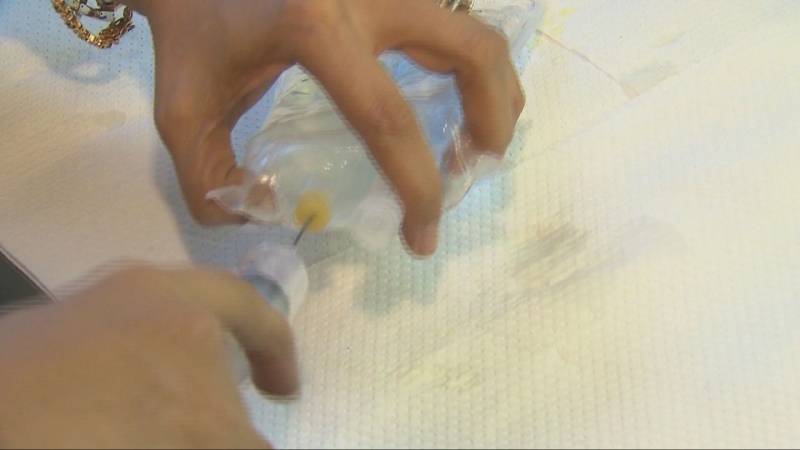

As a result, workers for Signature on the St. Lawrence are spending time fixing welds, replacing porous steel plates, defective bolts, poorly aligned holes and sometimes giving parts a fresh coat of paint because they've been scratched.

So far crews have repaired 2,000 defects, with one steel beam having 300 flaws that were repaired before being used. The defects were spotted before the parts were installed, said Daniel Genest, spokesperson for Signature on the St. Lawrence.

But SSL says that every one of the 11,000 pieces going into the bridge's construction will be up to code before it is in place, and these defects are no cause for concern.

“It’s typical of any fabrication process to have more of these problems as you start a process and then as you improve over time that tends to mitigate itself,” said Genest, adding that the consortium has no interest in building a shoddy bridge.

"Clearly we are delivering a bridge which has a design life of 125 years. We're in a public-private partnership so over the 2015 to 2018 we're building a bridge, out to 2019 the highway, then because we're in a public-private partnership over the next 30 years from 2018 to 2048 we have the responsibility of maintaining the existing bridge, so we're accountable to build and design correctly to minimize the cost of maintenance because if there's a problem in the next 30 years we are responsible for paying those costs," said Genest.

Federal Transport Minister Marc Garneau told reporters in Ottawa Monday that the structure "is in good hands," adding that all the parts for the new Champlain Bridge are inspected and are repaired or rejected when there are non-conformities.

While the majority of parts come from Quebec, some come from a firm in Spain. The Canadian Institute of Steel Construction said that’s the problem, since each country adheres to its own quality control.

“The level of welding, that is not up to par, does not meet code standards,” explained Hellen Christodoulou, regional director for the institute. “This is critical. This would not be an issue for any Canadian and/or Quebec fabricator.”

Christodoulou said the consortium should be looking at the final cost, not the initial bid.

“There are many adjacent costs, peripheral costs, that are not just directly involved with the material, so when we’re talking about a project, we’re talking from A to Z, which includes a timeline for completion,” she said.

Earlier this year, the project was slightly delayed by a number of strikes and problems getting heavy equipment and material to the site.

Still, the consortium is optimistic.

“There’s more workforce: an increase of 25 per cent. We went from 650 to almost 900. More work shifts onsite and more quality control,” said Genest.

There have been delays in getting some parts to the bridge because of weight restrictions on the existing Champlain, but Genest said despite this, the $4.2-billion span is on track to be completed on by December 2018.